IN-SITU MECHANICAL PROCESSING MACHINE

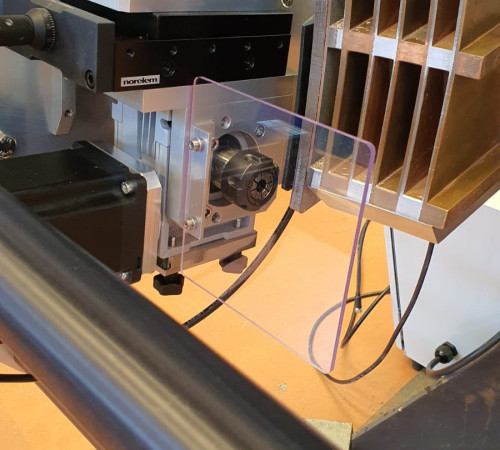

This tooling enables hybrid coupler tracks to be machined directly inside the Tokamak WEST chamber.

IN-SITU MECHANICAL PROCESSING MACHINE

The mission's challenge

The machining of dual-material components in situ, in a confined environment, without lubrication, and with high precision required a miniaturized design combining lightness, compactness, and rigidity.

Specificity

Multi-material machining with cutting parameters specific to each material.Technical characteristics

| Depth of cut | ≤0.1 mm |

| Surface finish after machining | Ra ≤ 6.4 |

| Environment | confined chamber |

| Operational | ambient |

| Temperature | 22 ± 3°C |

Operational characteristics

The operation to be performed is the re-machining of the external tracks of the LH2 coupler to remove 2.1 to 5 mm of material from the end tracks of the coupler.

Delivery times

This project was delivered in eight months, via the following stages:

- Project management

- Mechanical studies and analyses

- Manufacture of the tools required to inspect the components

- Manufacture

- Qualification tests

Certifications

This equipment complies with European standards 2006/42/EC.