AEro & spatial

Aerospatial challenges, performance and rationalization

An intensively competitive environment, worldwide with new players emerging, accompanied by an intensification of strategic and technogical disruptions.

Optimization and rationalizing of MGSE and other specialized equipment, are of paramount importance, in a constant search of excellence.

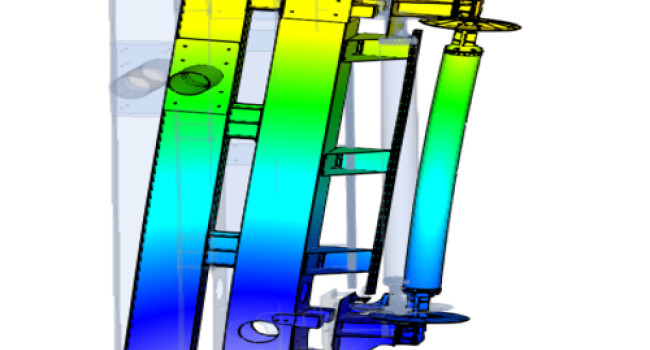

VIBRATION FRAME

to simulate flight vibrations.

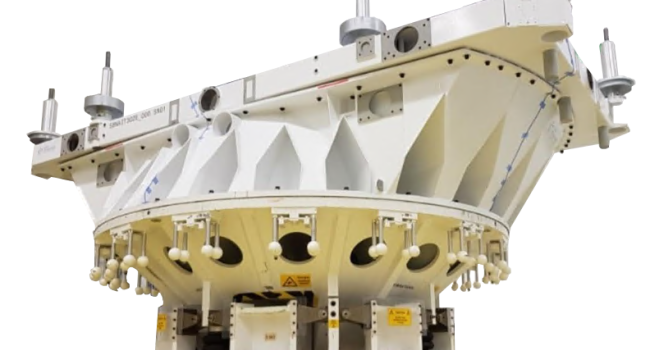

SPACECRAFT ROTATING & TILTING STAND

This stand allows handling, rotating and tilting of a spacecraft, a payload or equipment during all integration phases in cleanroom environment or at a launchpad.

Our strength: optimization from the initial design phase.

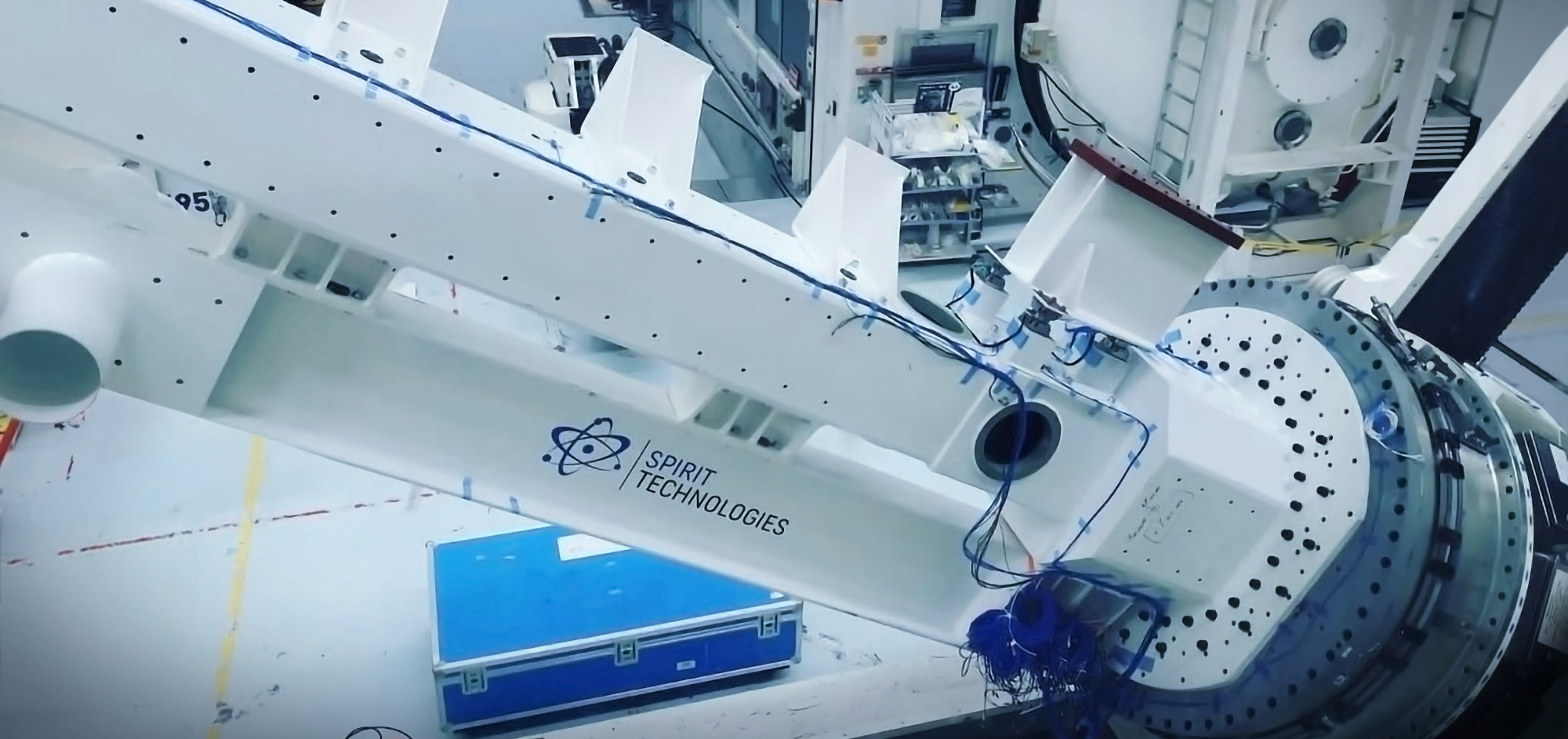

Historical partner of large Space and Aeronautical Groups, a specialist in advanced engineering and mechnanical engineering for complex environments.

Spirit Technologies designs and manufactures the MGSE necessary for the entire integration chain of a satellite, of a launcher and of their sub-units.

Accompanying you from the initial stage, from the moment you express your requirements, and specifications are formalized, brings a significant impact to the reduction of the final cost and time frame for each project. Of course, without compromising any functionalities or sustainability.

Industrialization of methods

Internally or within our Group, the industrialization of the MGSE mobilizes all its certified methods for the requirements of Space and Aeronautical sectors, guaranteeing an optimal integration.

- Precision machining

- Large scale sheet metal work

- Surface treatment

- Automation

- Full project management

- High precision geometric control (3D Scanner)

- Documentation and CE certification

The demand for acceleration

Confronted with markets that are increasingly competitive, players in the aeronautical sector, even more so than in the spatial sector, are accelerating the rhythm and rationalization of the production process. Performance and safety are essential in order to industrialize a new assembly line or carry out efficient maintenance.

SOLAR PANEL DEPLOYMENT STRUCTURE ON SATELLITES

Generic structure that can be multiplied to simulate the deployment of a solar generator in the vacuum of space.

WING TILTER

for Mirage 2000