Our expertise of complex mechanical units

From engineering to integration in situ

Spirit Technologies masters all the key stages of optimization in the industrialization of high value-added mechanical units, from the feasibility study to integration in situ.

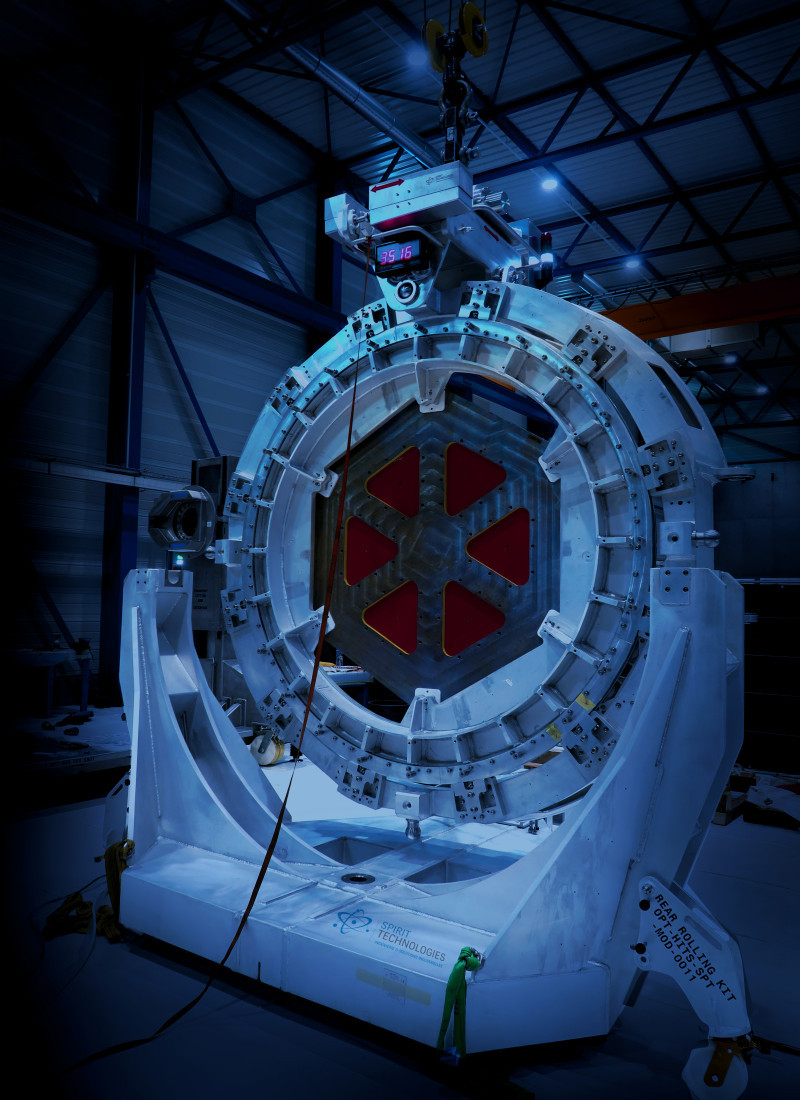

MGSE FOR DEPLOYMENT

of satellite solar generators

Mastering the key stages of industrialization

-

1- projeCt Management

A dedicated project manager manages your project from A to Z, by combining technical expertise, functional follow-up and quality communication, for an achievement that is 100% in line with our commitments.

-

2- DESIGN,

dEfinition & Mechanical analysIsInnovative solutions, streamlined from the initial design stage, and optimized in line with your objectives and constraints.

-

3- mechanical Expertise

• Mechanical feasibility studies

• Expertises following specific problems (wearing…)

• Equipment retrofit -

4- fabrication

All production and follow-up stages are conducted on our premises or within the Group: methodology, purchasing, machining, welding, dimensional control etc.

-

5- command control & MMI

Automatization and design of the Man-Machine interface for a simple, intuitive use of the equipment in real-time conditions.

-

6- ContrOL

qualification &

CertificationsDimensional controls using 3D optical measuring equipment and certifications by independant organisms, are completed by supplying CE documentation, as required..

-

7- Installation

& implementationCarried out by our technical teams on our premises, these are the final stages in order to guarantee an optimal integration worldwide.

The expertise of three engineering offices

Expertise acquired thanks to hundreds of projects in complex environments gives our engineering office a strong capacity to innovate and anticipate in situ behaviour.

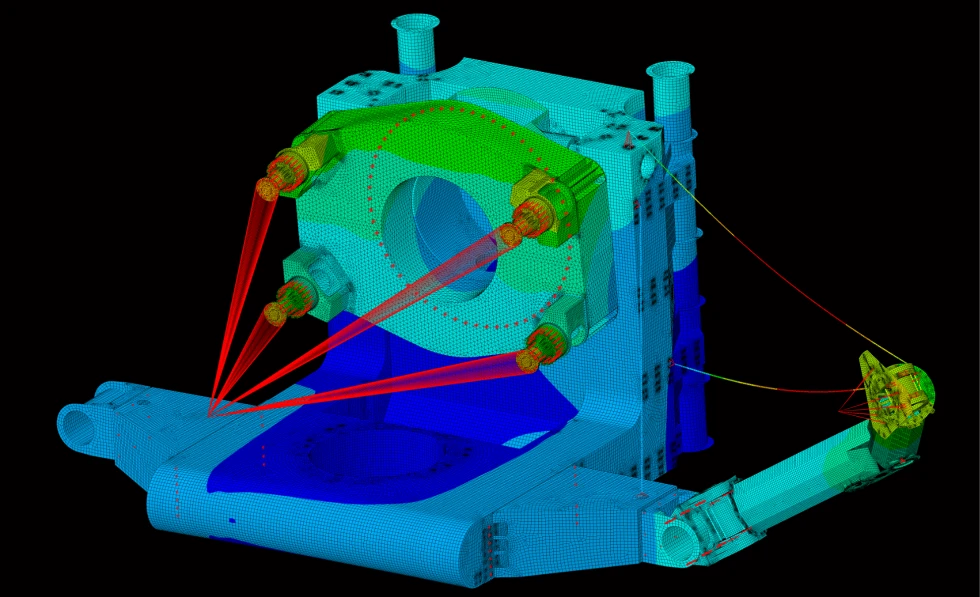

MECHANICAL ANALYSIS SKILLS

Analyses performed throughout the entire customer project cycle, from the call for tenders to testing.

CALCULATIONS

of antenna misalignment

static Analyses

Linear analyses.

Non-linear analyses (contact, material plasticity, large deformations).

Modal analyses.

Dynamic Analyses

Fatigue, dynamic response, transient response: half-sine shock.

Time-function stress.

Frequency response: sine inputs.

Optical performance verification.

PRESSURIZED EQUIPMENT ANALYSES

Internal / external pressure calculation.

VIBRATION TESTS

Prediction of vibratory response levels before testing and determination of input levels.

Analyses of the results and adaptation according to the product behavior.

Correlation of digital models and test results.

thermiC AND fluidic Analyses

Stationary or transient analyses.

Analysis of different types of exchanges: conduction, natural or forced convection, radiation.

Modelling of fluids: air or liquid (brine, dielectric oil etc.)

ThermiC

Heat transfer in solids (conduction)

Free, forced and mixed convection.

Radiation.

Heat sources (heat generation rate, thermal power, temperature)

Fluids

Hydraulic analysis of cooling circuits.

Determination of a velocity field.

Calculation of convection coefficients, calculation of load losses.

SEISM

Responses under seismic level using the PSD method (Power Spectral Density), in accordance with Eurocode 8.

We master complex environments such as space and aeronautical, naval defense and nuclear.

Spirit Technologies creates innovative solutions, that are optimized according to our constraints and your objectives.

We work together with you on design capacities and calculations.

Certified manufacturing capacities and integration

On our premises or those of our Group, the industrialization of the MGSE, systems and nuclear tools, or other custom-made or standard manufacturing benefit from all possible means provided that they respect the requirements of complex environments.

FULL-SCALE PROJECT MANAGEMENT

ENGINEERING and Project Management

SUPPLY

MANUFACTURING, assembly, testing, and certification

PACKAGING and transportation

PREcision MACHINING

MACHINING CENTRES

1500 X 800 X 800 and 800 X 500 X 500

MILLING / BORING MACHINES

5000 X 2000 X 1000, 1500 X 400 X 600, 13 and 16 m machining

NUMERICAL CONTROL LATHES: 400 X 1500 and 120 X 300

VERTICAL LATHE: Diam 4000 X 5000

WIRE CUTTING

FANUC wire cutting, capacity 400 X 400 X 300 mm

LARGE-DIMENSION BOILERMAKING

TIG / MIG / COATED ELECTRODE

Generators, direct current, alternating current, and pulsed current.

Inverter.

Welder qualifications (QS) and welding procedure specification (WPS) drafting.

MATERIALS

Steel and stainless steel.

Copper, aluminum, titanium, and their alloys.

STANDARDS

AQUAP, ASME, NFEN, RCCM...

SURFACE TREATMENTS

STAINLESS STEEL

Pickling, passivation, sandblasting / microblasting, electrolytic polishing.

CARBON STEELS

Sandblasting / microblasting, fluid paint / epoxy powder, zinc and bichromate coating, galvanization, chemical nickel plating, Fluoromide 1070 coating (Teflon coating).

ALUMINUM

Stripping / passivation, alodine / Surtec;

OAS / OAD / OAC.

AUTOMATION

SYSTEMS controls

PROCESS

ELECTRICAL engineering

HIGH-PRECISION GEOMETRIC INSPECTIONS (3D SCANNER)

THREE-DIMENSIONAL MEASURING MACHINE (CMM)

Temperature compensation from 16°C to 26°C, capacity: 1000 x 1000 x 800 mm.

3D SCANNERS ON OPTICAL CMM

KEYENCE WM 6000: measuring range 25 x 11 x 12.5 m, high precision 0.025 mm;

KEYENCE XM 5000: measuring range 2 x 1.20 x 1 m, high precision 0.003 mm.

FARO LASER TRACKER

INTEGRATION

BUILDING: 500 m² x 10 m, 12-ton bridge (7.5 m under hook)

ASSEMBLY

QUALIFICATION tests

CE CERTIFICATION

CE MARKING

NORMATIVE documentation

MAINTENANCE manuals

JUSTIFICATIONS

MGSE

for telescope intregration

The experience of cutting-edge technology

With 25 years project management experience in diverse extremely demanding sectors, we've developed specific technological know-how.

8 000 hours are invested each year in R&D, with numerous patents.

FInd out more about our experience in your sector:

CMM inspection

for large dimensions