NUCLEAR & ENERGY

Reliability and robustness, at the heart of energy industrialization

For over 25 years, we have been accompanying actors in the nuclear field to secure each step in their most demanding projects, from design to in-situ implementation.

Innovative material, adapted processes, proven solutions in highly complex contexts. Our mastery of engineering and advanced technology will bring serenity to your projects.

NUCLEAR FUSION TOKAMAK

Development of diagnostics for controls or measures, and development of panel components facing the plasma

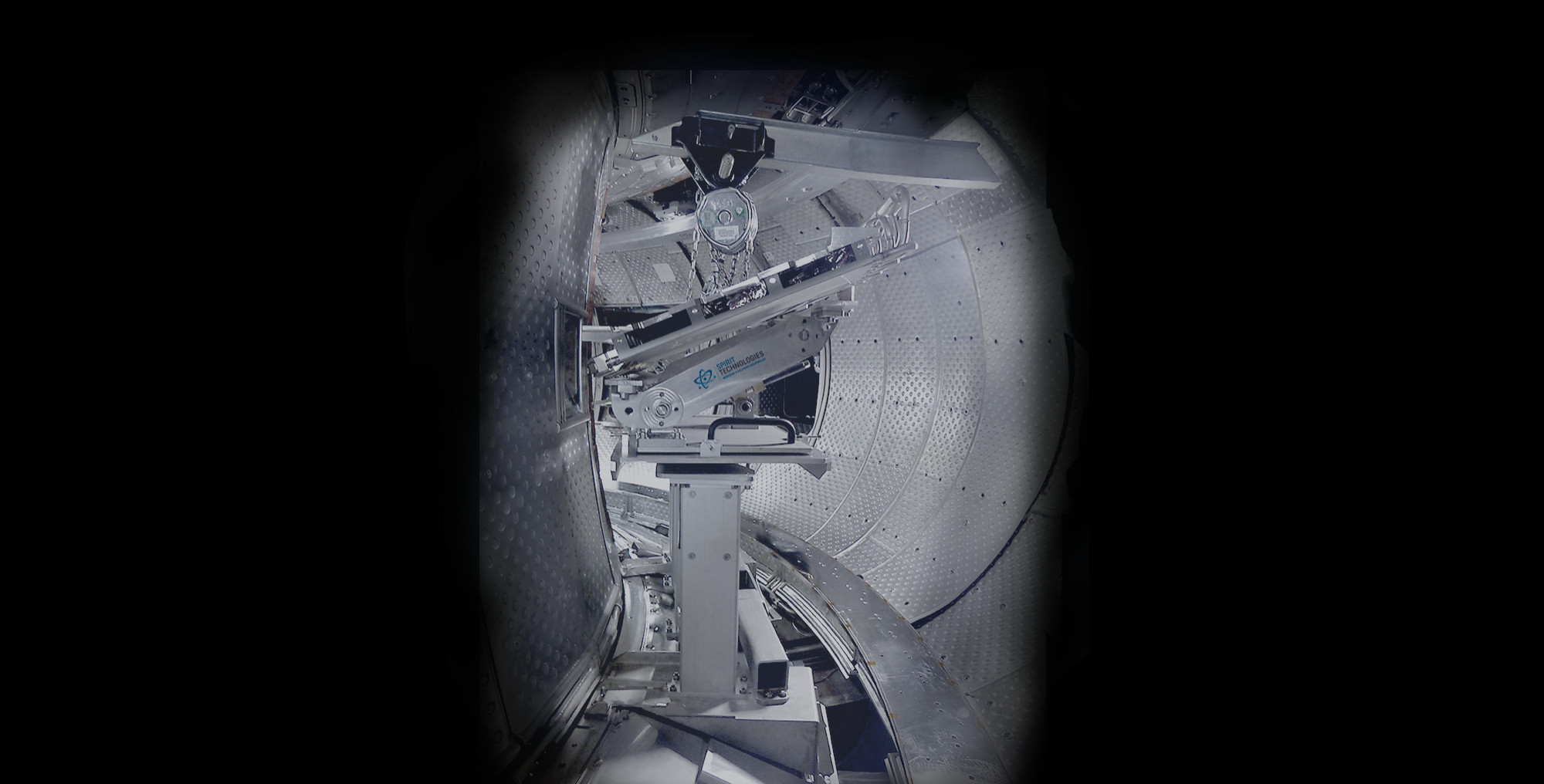

WEST TOKAMAK

Integration tools from the top divertor of the reactor

Your multi-disciplinary partner to solve the most complex challenges.

A dedicated, experienced partner from the very start of the design phase, to accelerate implementation (specifications, materials, processes) for your nuclear engineering solutions.

The agility of a small business with specialized expertise, yet part of a powerful, multi-disciplinary Group: ready to manage the entire industrialization chain, from methods to realization and on-site assembly.

We can accompany you to identify your requirements and formalize specifications. We will also optimize costs, leading to a considerable reduction of the final cost and project timeframe, without compromising on performance or the longevity of the developed solutions.

Development of mechanical engineering solutions

On our premises or on those of the Group, the industralization of the systems and nuclear tools will benefit from all means that comply with the requirements of complex environments of fusion or of fission and other energies (hydraulic, fossil etc.)

- ENGINEERING & R&D

- FULL PROJECT MANAGEMENT

- LARGE-SCALE BOILER-MAKING STAINLESS STEEL, ALU, BLACK STEEL

- WELDING PROCESS

- SURFACE TREATMENTS SUCH AS ELECTROLYTIC COPPER PLATING

- PRESSURE EQUIPMENT

- ULTRA VACUUM TECHNIQUE

- AUTOMATISMS

- PRECISION MECHANICS

- HIGH PRECISION GEOPMETRIC CONTROLS (SCANNER 3D)

Security is our top priority

Spirit Technologies is experienced in complex environments and certifies all its integration tools, specialized machines, structures, components and systems adhering to RCCM, CODAP, ASME codes and respecting all European standards in force.

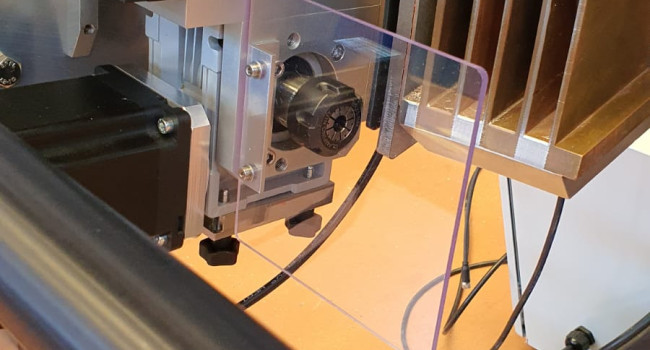

COMPONENT FOR SUPERCONDUCTOR

Connector housing enabling contact mechanics analysis.

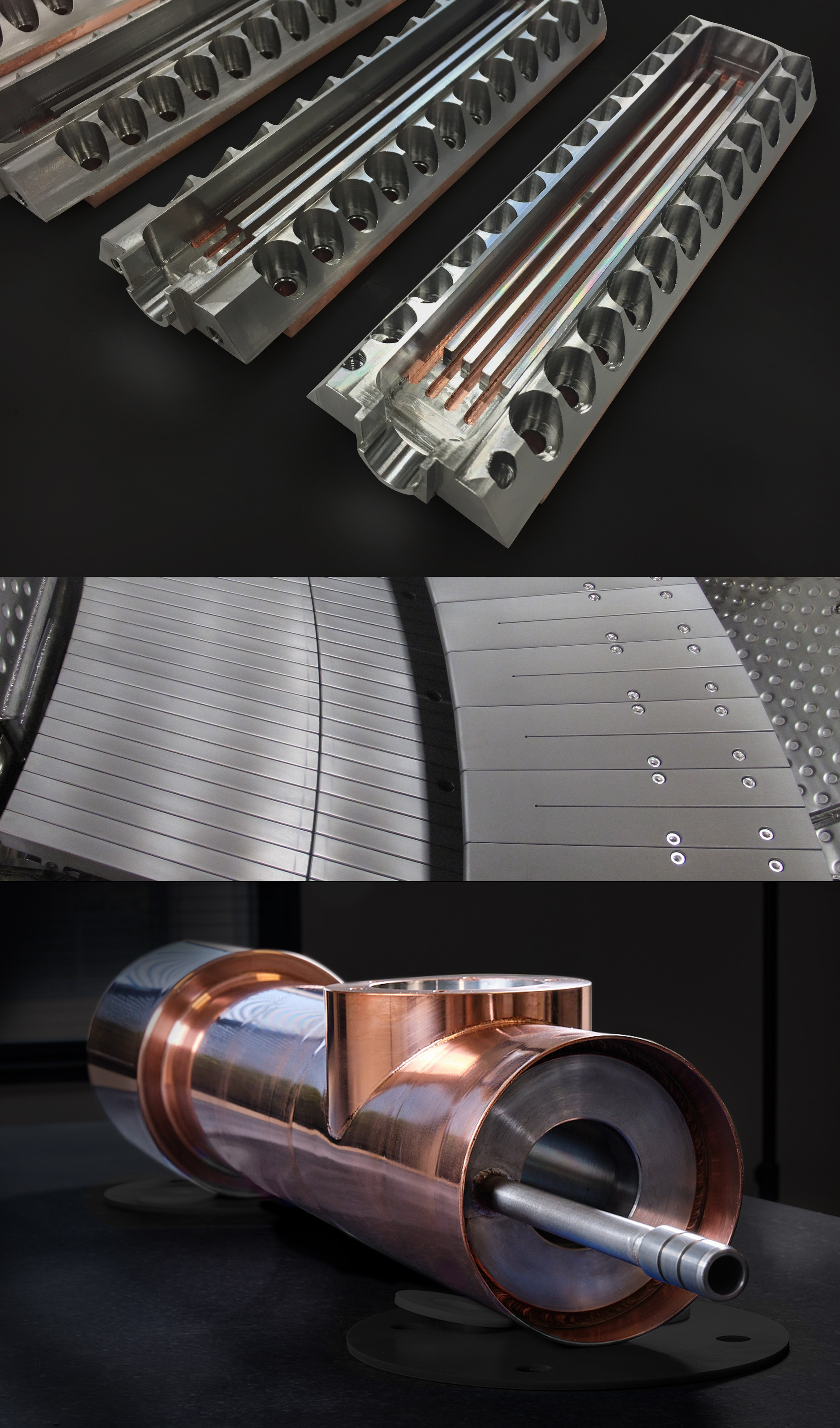

WEST TUNGSTEN DIVERTOR

Actively cooled copper and tungsten baffles.

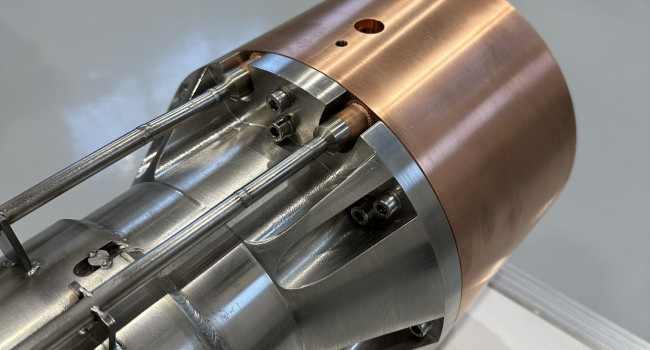

HF RESONATOR

Internal stainless steel conductor with pressurized cooling system and copper coating to optimize electrical characteristics.