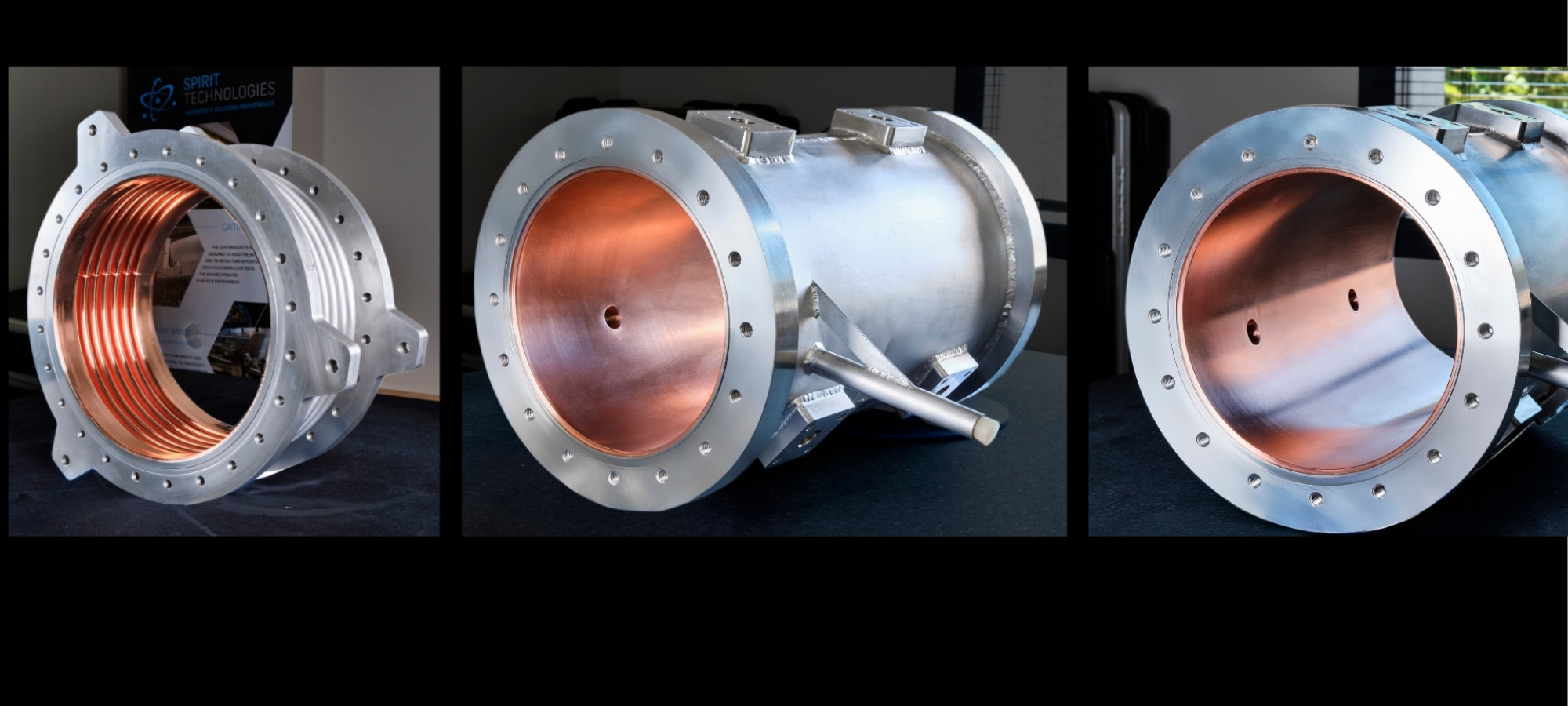

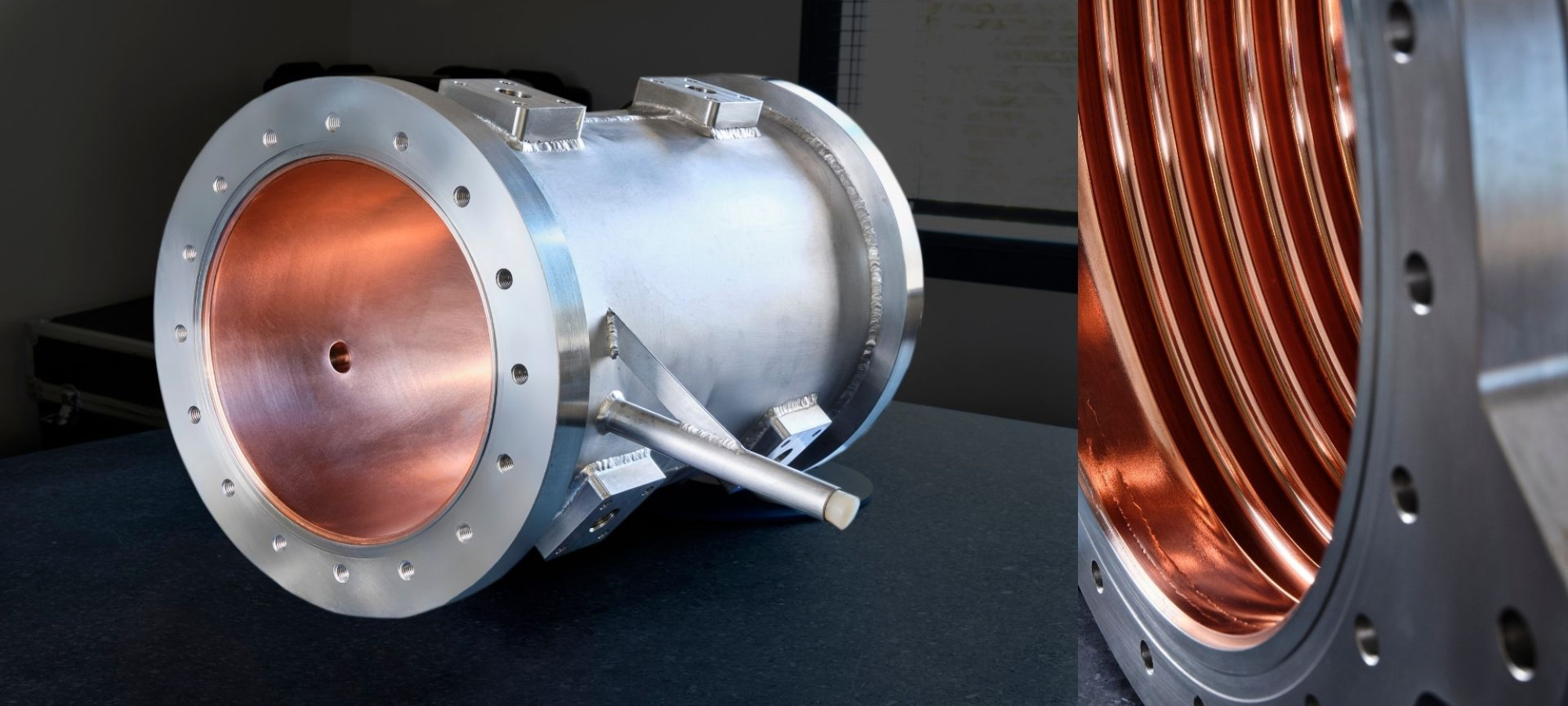

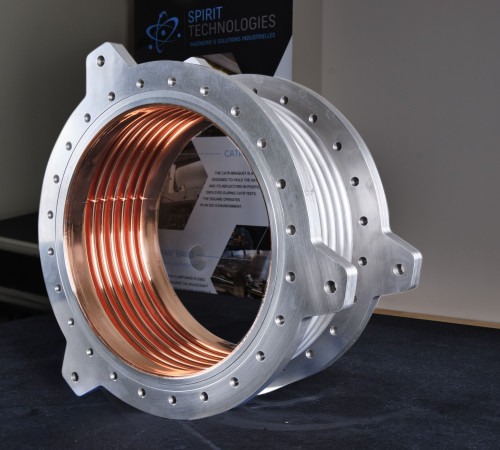

HF RESONATOR

R&D for the development of the ITER ICRH system, aimed at testing radiofrequency window prototypes under operational conditions in the Tokamak WEST reactor.

The stainless steel parts have a copper coating on the surfaces in contact with the electromagnetic field, which is intended to improve the electrical conductivity of the material.

The mission's challenge

The combination of multiple factors and their complexity has led to significant investment in industrialization and methods to successfully manufacture components:

- pressure equipment

- ultra-high vacuum sealing

- copper deposition, surface treatments

- machining of complex parts

- dimensional accuracy

Specificity

A highly multidisciplinary project that brought together all the expertise within the Spirit Industries group.Technical characteristics

| Min. temperature | 100°C |

| Max. temperature | 250°C |

| Min. pressure | ultra-vide |

| Max. pressure | 82 bar |

| Voltage | 50 kV |

| Power | 2,5 kA |

Operational characteristics

This test bench is a radio frequency coaxial resonator (~50MHz) made of tubular aluminum, copper, and stainless steel parts. The resonator has five different configurations in order to test several types of prototype windows.

Delivery times

The various stages were completed over a period of 18 months:

- Project architecture

- Project management

- Industrialization and methods

- Manufacturing specifications

- Documentation

- Production

Certifications

This equipment is manufactured in accordance with standard EN 13445 and directive No. 2014-68-EU (pressure shells).

Requires application of standard ISO 3834-3 (welding) and COFREND 2 certification for personnel (inspections and testing).