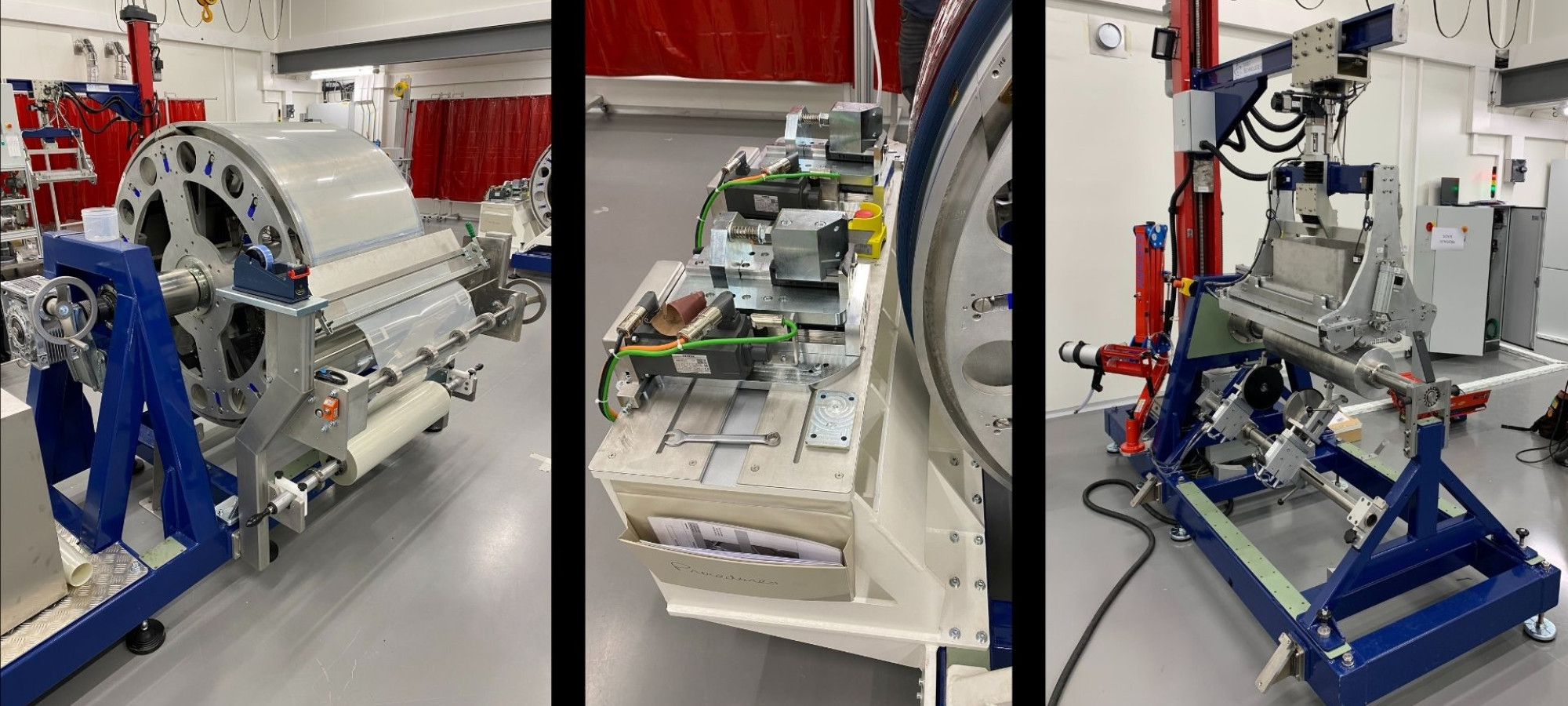

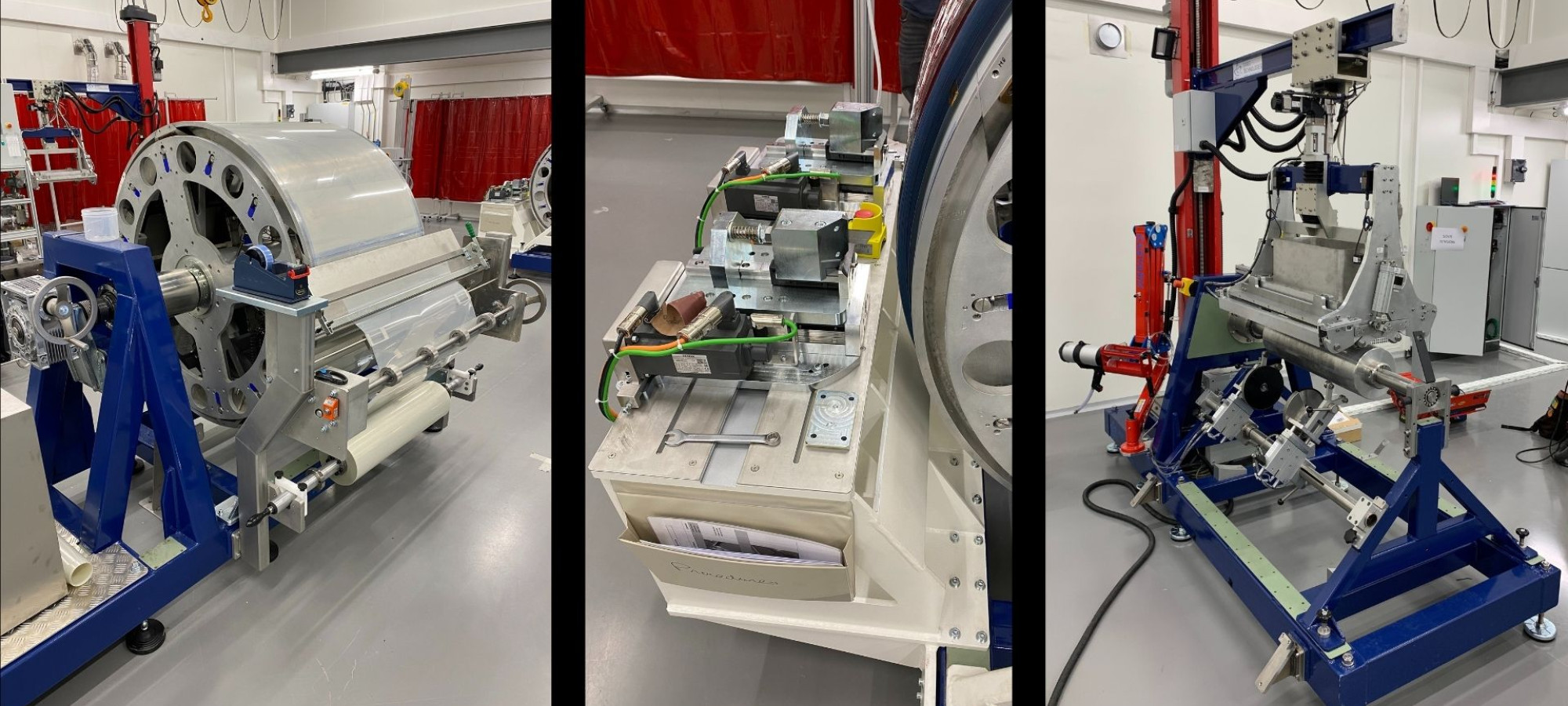

SILICONE RING PRODUCTION LINE

A production line has been developed for two different diameters.

The purpose of the line is to construct a ring by winding successive layers of 50-micron silicone onto aluminum drums.

SILICONE RING PRODUCTION LINE

The mission's challenge

The homogeneous layering of silicone required precise adjustments to temperature and viscosity, while keeping up with the desired production rates.

Specificity

Production management in ISO 8 roomTechnical characteristics

| Dimensions | 2500 x 1300 x 2900 mm |

| Thickness of the film layer | 50 µm |

| Rotation speed of the drum | 0.166 tr/min |

| Drum diameter | 200 and 1200 mm |

Operational characteristics

The process involves depositing silicone rings in 10 mm increments by winding 50 µm film onto aluminum cylinders. Polymerization is carried out using an infrared heating system.

Delivery times

The project was delivered in 15 months:

- Project management

- Mechanical studies and analyses

- Construction of the tools needed to inspect the components

- Manufacturing

- Qualification tests

Certifications

This equipment complies with European standards 2006/42/EC.